QUALIST

BRIDGE

ATTAIN FASTER AND HIGH-QUALITY PRODUCTION

THROUGH MINIMUM RESOURCE CONSUMPTION.

Qualist BRIDGE® allows you to make direct product quality by making strategic decisions while being aware of the data, to make predictive maintenance operations, optimize production and more.

Qualist BRIDGE® is an Industrial Analytics Software specifically built to meet the requirements of manufacturing and works on the Qualist Industrial IoT Platform®.

-

Automated KPI Reporting

Provides real-time and historic information about the most important metrics of performance.

-

Quality Management

Provides advanced analytics and operational intelligence. Delivers visibility and insight into machine and business data.

-

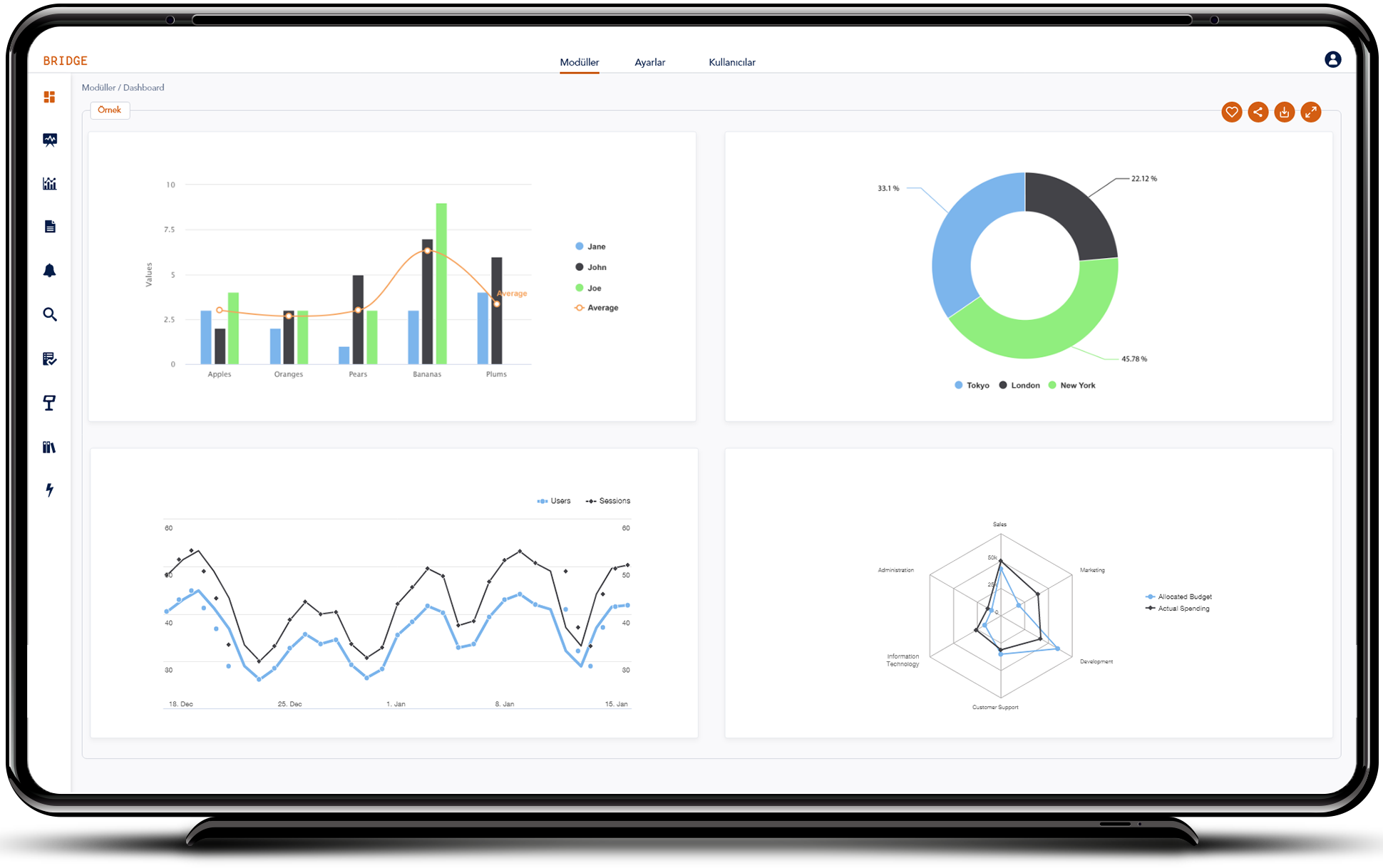

Real-time Dashboards

Customisable dashboards based on individual needs. Allows to watch and measure all operations by all internet of things.

-

Machine Learning and Predictions

As the data collected from different resources with machine learning method are sampled, decision tree models are developed to ensure accurate predictions.

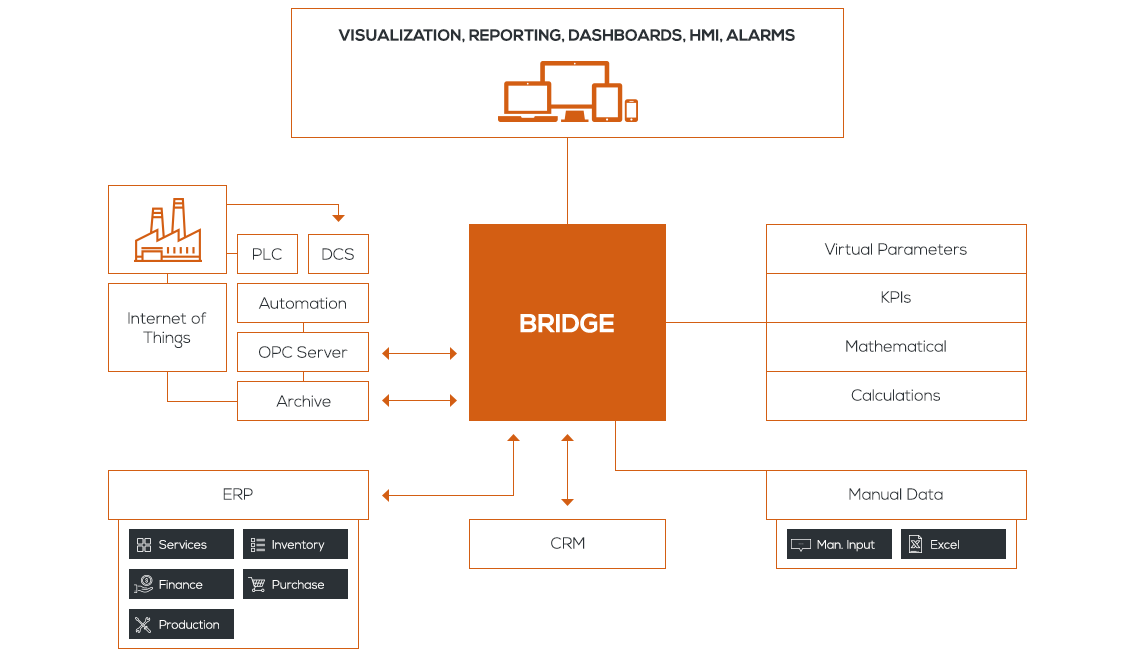

BRIDGE DATA COLLECTION ARCHITECTURE

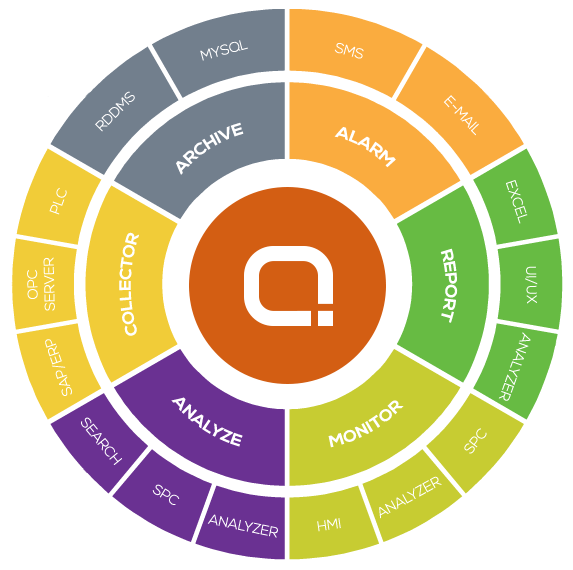

- ARCHIVING

- Storage, backup and compression of data through a multilayered architecture in a secure local or cloud database.

- DATA COLLECTION

- High quality reliable data gathering and measuring through multiple channels.

- MINING

- Detect, extract, transform, cluster, classify and present data sets.

- ALARM

- For each variable data in the database, it provides the option to create multiple condition alarms with different alarm type options such as SMS, e-mail and daily e-mail report.

- REPORTING

- Filtered for a set time range, at the selected frequency and through various mathematical functions, the output datacan be imported to and analyzed on an Excel file.

- IMAGING

IMPORTANT FEATURES

-

EASY AND QUICK SETUP

A facility with a capacity of 15 PLC and 2000 data-point on average can be equipped with Qualist Bridge® within a week. In addition, the setup process requires no down-time.

-

ACCESS FROM ANYWHERE

Thanks to its sensitive design structure, you can easily access Qualist Bridge® through all platforms.

-

CUSTOMER BASED AND CONTINUOUS R&D

We are continuously developing customer-driven features to meet the changing requirements of their operations.

-

MACHINE LEARNING

Our data science team uses machine learning algorithms created by statistical methods. This makes the relation between data detectable and the system prepares modellings intended to form predictions.

-

TECHNICAL SUPPORT

We have a dedicated team for technical support ready to serve our customers.

-

PREVENTIVE MAINTENANCE

Qualist Bridge has the right early detection tools to prevent unplanned down-times.

NEED FURTHER INFORMATION?

Fill out the communication form below and we would be more than happy to answer any questions you might have as soon as possible.